Packaged Modular Pumping Station NS-AMMA

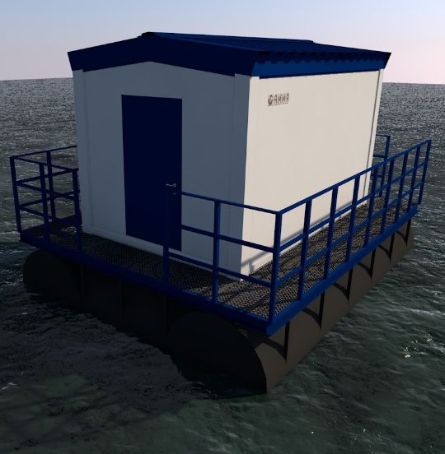

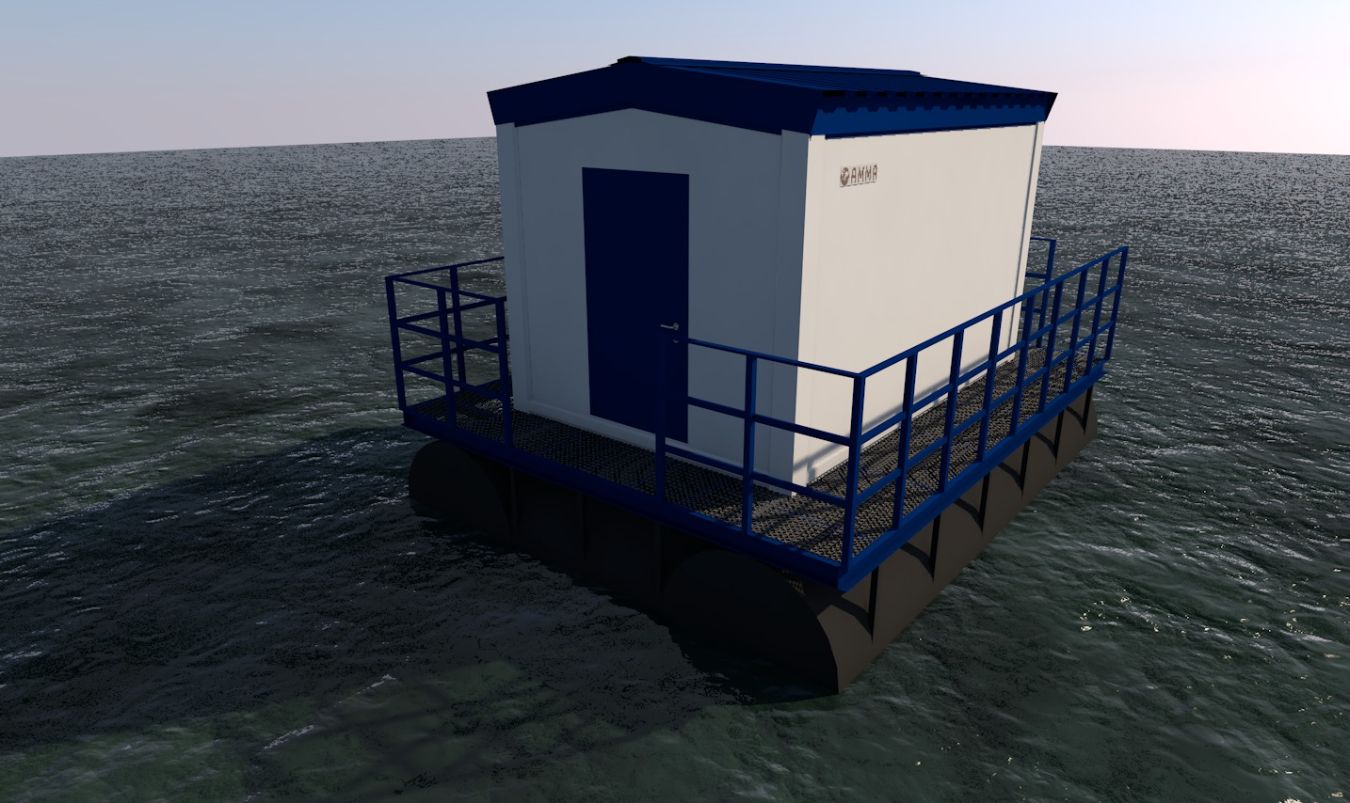

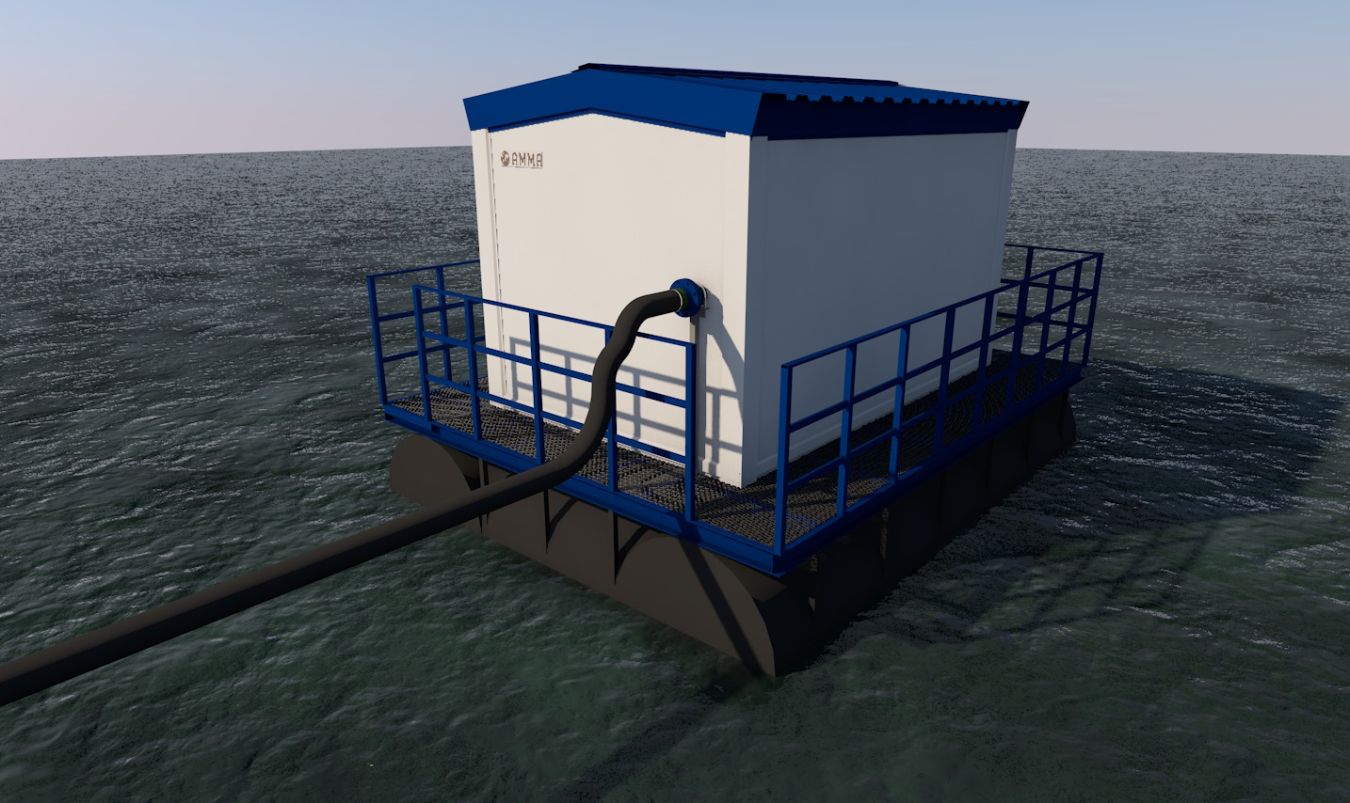

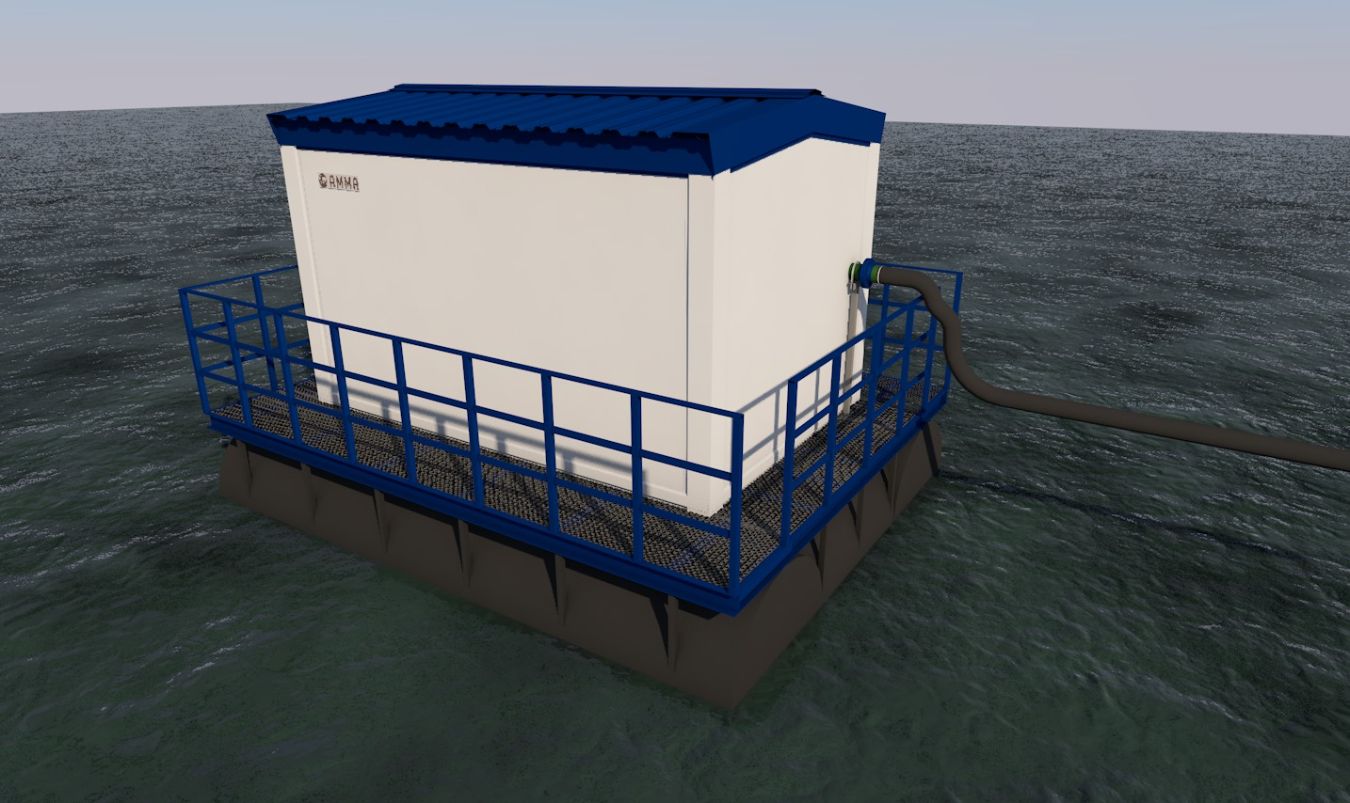

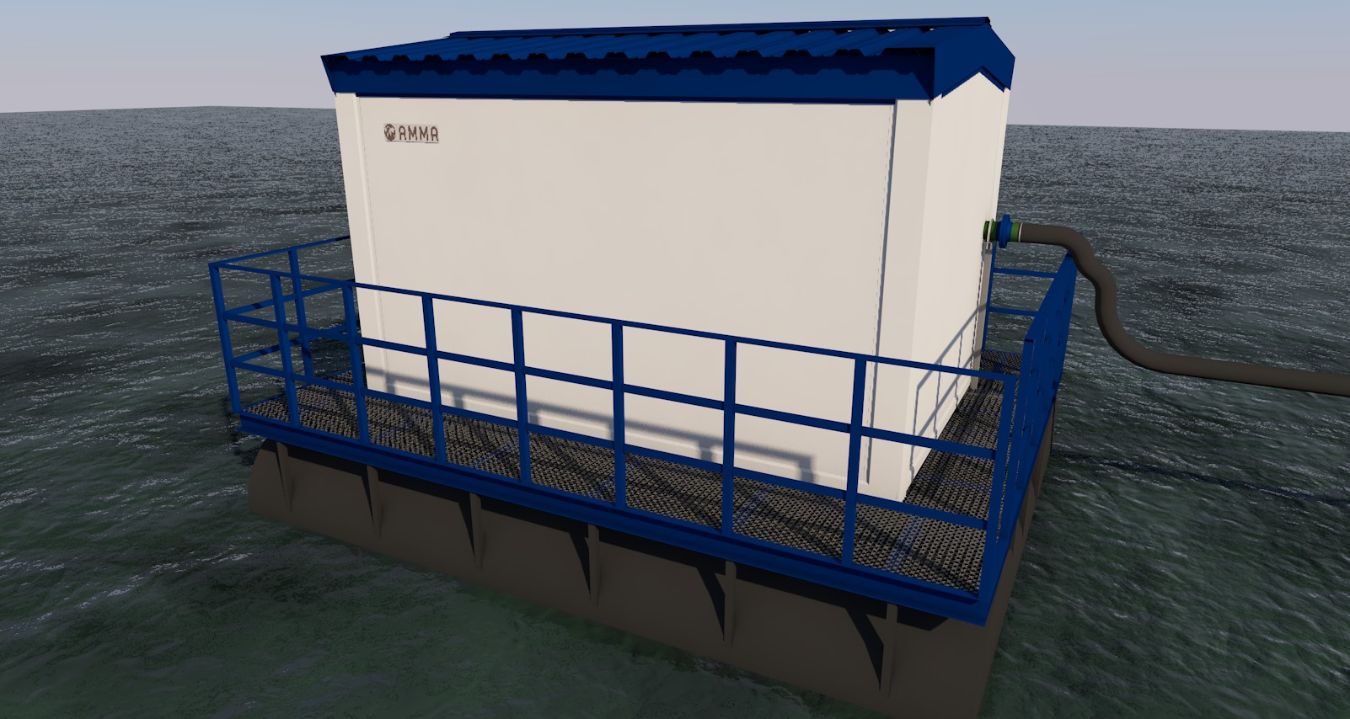

Floating Pumping Station NS-АММА

DESCRIPTION

Three-layer sandwich panels with insulation made of non-combustible, environmentally friendly material are used as enclosing structures.

The Floating Pumping Station is a prefabricated structure consisting of metal pontoons. It facilitates transportation of the station and makes it possible to mount it at the point of water intake without the use of powerful lifting transport.

The Pumping Station is supplied to the Customer as fully prefabricated. It has a fixture for easy mounting on site.

OPERATING FEATURES

Features of the Floating Pumping Station operation:

- easy to use;

- climatic version is F;

- only modern, environmentally friendly materials are used;

- submersible pumps are mounted on the pontoon and are permanently in the water;

- works fully automatically;

- at least 25 years service life;

- fast production;

- easy to transport;

- affordable cost.

SCOPE OF DELIVERY

The SPE AMMA, LLC Pumping Station scope of delivery includes:

- A complete pumping station with heating, ventilation, lighting, earthing, instrumentation and automation, small tools;

- external supports and consumables for mounting;

- set of spare parts and materials for the warranty period;

- technical documentation (data sheet, operation manual).

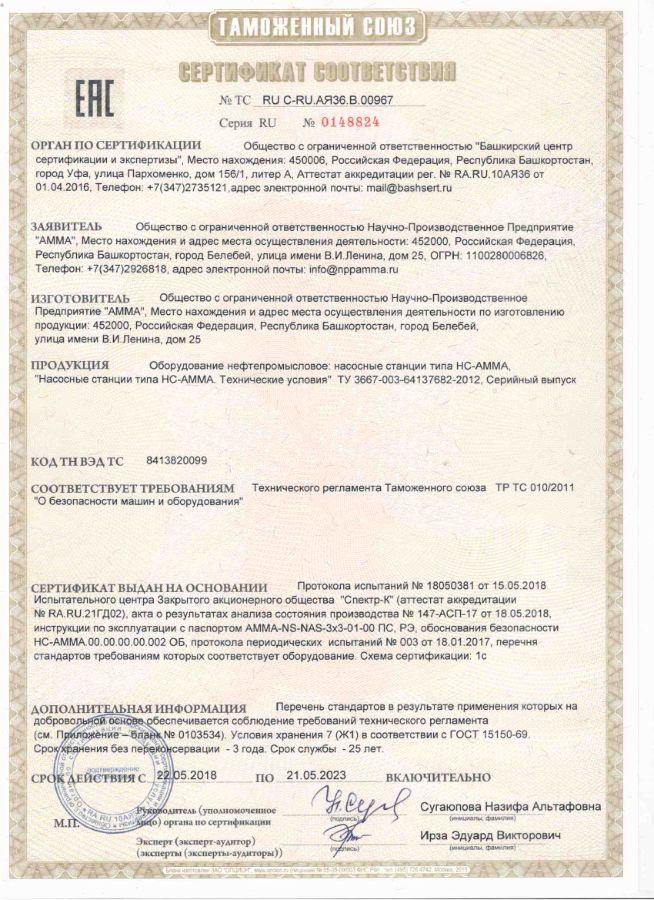

QUALITY

Metal structures are manufactured in accordance with the requirements of GOST 23118-2012 Steel Construction Structures and SP 53-101-98 Fabrication and Quality Control of Steel Construction Structures.

The pipe ends shall be plugged during transportation and storage to prevent the ingress of precipitation and foreign bodies.

Shut-off valves in the piping is provided for tightness class A in accordance with GOST R 54808-2011 Pipeline valves.

The automation of the Floating Pumping Station includes:

- Control and condition monitoring of pump units;

- Collection and transmission of signals from sensors to the control room.

The automation section provides output of the following signals about the operation of the Pumping Station to the control room:

- excessive pressure;

- flow rate;

- indoor temperature;

- gate valves state (open/closed);

- pavilion flood alarms;

- low water level alarm of the reservoir (dry run protection of the pump);

- alarm system for entering the pavilion (control of unauthorized access to the premises);

- number of pumps running;

- pump failure.

Pump unit control includes:

- frequency regulation;

- automatic switchover of pumps to standby.

Signals from sensors and frequency converters go to the automation cabinet, located in the room of the Floating Pumping Station.

Communication between the control cabinet and the control room can be provided by optical or GSM radio channel.

The heating is electric. Temperature controllers are mounted on the heaters to adjust the temperature mode.

The building is provided with permanent natural supply and exhaust ventilation in the amount of one air change per hour.

The inflow is from an insulated air valve with manual control.

Exhaust ventilation is provided with natural induction, due to the installation of a deflector. A manually operated air damper is provided to regulate exhaust air in the system.

All air ducts are made of thin sheet galvanized steel in accordance with GOST 14918-80. All heating and ventilation equipment is grounded in accordance with the requirements of the EIC. The unit is mounted, tested, started in accordance with SP 73.13330.2016 Internal Sanitary Engineering Systems of Buildings.

The electricity supply is of I category of reliability. The voltage is 380/220V.

Consumers are supplied with power from the Input Switching Device cabinet installed inside the pavilion.

Power and lighting networks are made by cable ВВГнг(А)-LS, laid in metal trays. The emergency lighting network is made by ВВГнг(А)-FRLS cable.

The electrical wiring is selected in accordance with GOST R 50571.5.52-2011 Electrical Wiring and the EIC, Edition 7, Section 7, Chapter 7.1.

Electric lighting of the Floating Pumping Station is provided in accordance with SP 52.13330.2011 Natural and artificial lighting and ВСН 34-91 Industrial standards of artificial lighting of oil and gas industry.

The lamps are selected according to the environment characteristics and the room purpose. Lighting is controlled by switches installed near the entrance to the Modular Container.

The following types of lighting are provided:

- working;

- outdoor;

- emergency;

- repair.

The electrical wiring of the distribution and group network of the station is made according to the TN-S system.

For electrical safety purposes, protective grounding of exposed conductive parts is provided by means of special conductors connected with a separate clamp to PE conductors.

Protective earthing of electrical consumers is provided with a special additional wire (PE protective conductor).

To protect against direct lightning strikes, 3.5 m high lightning rods are used. They are mounted on the roof of the building.

Lightning protection is done in accordance with RD 34.21.122-87 Instruction on the lightning protection of buildings and structures and SB 153-34.21.122-2003 Instruction on the lightning protection of buildings, facilities and industrial communications.

The NS-АММА Pumping Station shall be loaded onto the vehicle by means of cranes of suitable lifting capacity, equipped with lifting means and pulling devices.

The NS-АММА Pumping Station may only be lifted by the elements provided for this purpose.

It is prohibited to lift the НС-АММА Pumping Station by other means.

The NS-АММА Pumping Station shall be secured to vehicles in accordance with the loading and securing specifications for each type of transport.

The dimensions of the NS-АММА Pumping Station comply with the requirements of the loading dimensions of the Technical Conditions for Loading and Securing Cargo of the Russian Ministry of Railway Communication.

The AMMA guarantees that the Gaseous Fire Supression Station complies with the technical documentation, provided the customer complies with the conditions of transport, storage, mounting and operation.

The warranty period is 12 (twelve) months from the date of mounting or 18 months from the date of delivery, whichever comes first.

The service life of the Gaseous Fire Supression Station is 8 years. The warranty periods of the components used in the Gaseous Fire Supression Station are established by the manufacturers of these products, who are responsible for their quality.

A warranty period may be agreed upon with the Customer.

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.