Packaged Modular Pumping Station NS-АММА

Pumping Station for Reservoir WateR NS-АММА

INTENDED USE AND DESCRIPTION

The block dimensions are selected depending on the number and size of pump units and availability of other process equipment, and based on the possibility of their transportation by rail and road transport.

The blocks are equipped with technological equipment, lifting mechanisms (hoists) for mounting (dismantling) of equipment, ventilation systems, heating, electric lighting, instrumentation and automation, providing reliable operation of the pumping station without the constant presence of service personnel.

Three-layer sandwich panels with insulation made of non-combustible, environmentally friendly material are used as enclosing structures.

Automatic emergency protection and blocking of technological equipment in case of emergency situations. Emergency and process alarms are transmitted by the control system to the operator's room.

ADVANTAGES

The main advantages of the Pumping Station:

- complete set;

- climatic version is F;

- at least 25 years service life;

- work automation;

- only modern, environmentally friendly materials for the blocks manufacture are used;

- an unlimited number of mounting/dismantling cycles at the Customer's sites;

- low cost.

SCOPE OF DELIVERY

The SPE AMMA, LLC Pumping Station scope of delivery includes::

- a complete pumping station with heating, ventilation, lighting, earthing, instrumentation and automation, small tools;

- external supports and consumables for mounting;

- set of spare parts and materials for the warranty period;

- technical documentation (data sheet, operation manual).

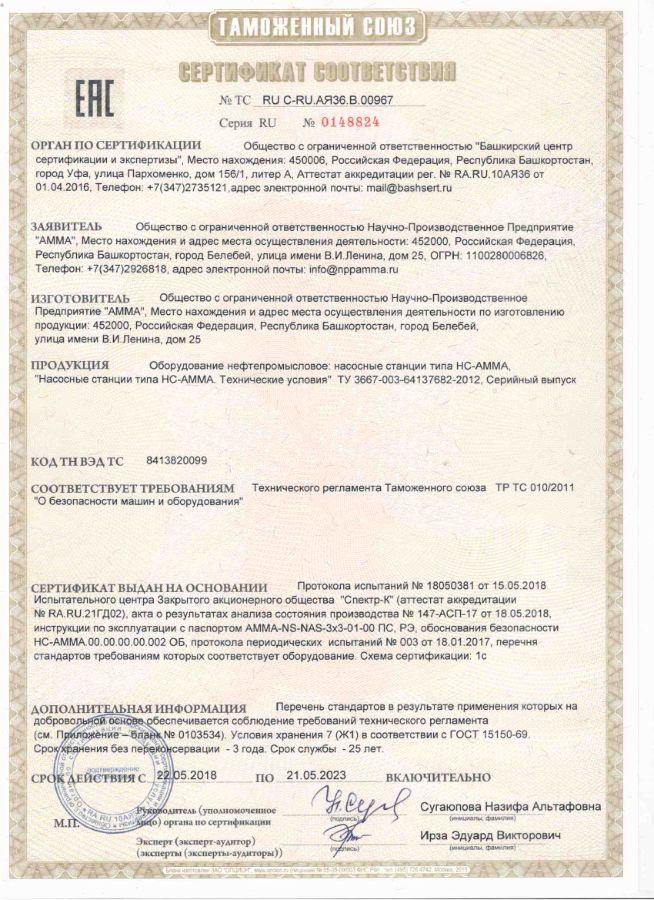

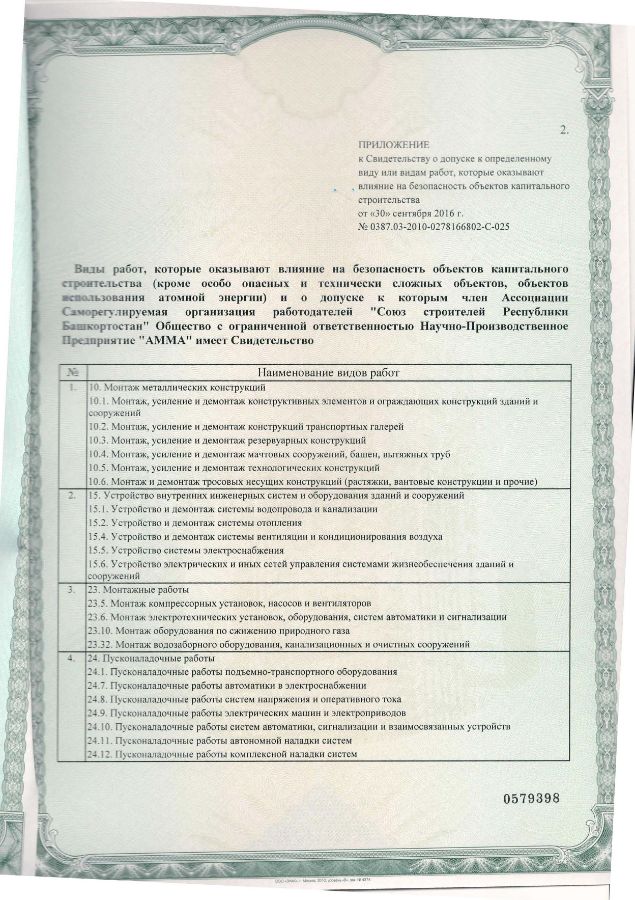

QUALITY

Metal structures are manufactured in accordance with the requirements of GOST 23118-2012 Steel Construction Structures and SP 53-101-98 Fabrication and Quality Control of Steel Construction Structures. The load-bearing structures and piping are exposed to a corrosion protection treatment.

The level of automation of the chamber makes it possible to operate without the constant presence of service personnel directly at the units and apparatuses.

Shut-off and control valves of flange design, tightness class in the gate is A according to GOST 54808-2011 Pipeline valves.

Piping in the unit is made with free access for repair during operation.

The placement of shut-off valves in the suction and discharge pipelines ensures that any of the pumps, check valves and main shut-off valves can be replaced or repaired, and that the pumps can be checked for performance without violating the water supply continuity requirements.

A water meter is provided at the water inlet to measure water consumption.

The design of the pump station meets the requirements of ВНТП 01/87/04-84 Facilities of gas and oil industry, made with the use of block and block-complete devices.

The pipe ends shall be plugged during transportation and storage to prevent the ingress of precipitation and foreign bodies.

Process pipelines are mounted in accordance with GOST 32569-2013 Industrial steel pipelines. Requirements for design and operation in explosive and chemically dangerous industries, approved by order of the Federal Agency for Technical Regulation and Metrology dated 08.04.2014. N331-cт, SNiP 3.05.05-84 Process equipment and pipelines.

The structure is heated and ventilated as per SP 60.13330.2012 Heating, Ventilation and Air Conditioning, ВНТП 3-85 Standards of Process Design of Gathering, Transport, Oil, Gas and Water Treatment Facilities in Oil Fields.

Electric heaters are mounted in the Modular Containers to maintain the specified air parameters in the rooms.

For the process unit, it is accepted in explosion-proof design, as for the Low-Voltage Package Module Unit it is in general-industrial version.

The equipment is mounted in places accessible for inspection and maintenance, free of process piping and equipment.

The air temperature in the Modular Containe room is assumed to be at least +5°C.

The outside air design parameters are the following: are the average temperature of coldest five-day period (term of 0.92) is minus 45 °С.

In the process room of the water pumping station, there is permanent supply and exhaust natural ventilation providing a single air exchange and periodic mechanical exhaust ventilation providing an 8-fold air exchange.

The supply natural ventilation system of the process unit is equipped with an insulated air valve with manual control.

Exhaust natural ventilation is carried out through the deflector.

Mechanical exhaust ventilation is provided by a radial fan.

All ventilation equipment of the process unit is accepted in explosion-proof version.

In the room of the Low-Voltage Package Module unit, an air conditioning system is provided to remove excess heat from the operating equipment.

The natural intake ventilation system of the Low-Voltage Package Module unit is equipped with an electrically heated manual air damper. All ventilation equipment of the Low-Voltage Package Module Unit is accepted in general-purpose design.

All air ducts are made of thin sheet galvanized steel in accordance with GOST 14918-80.

Automatic shutdown of equipment of ventilation and air conditioning systems is provided in the event of a fire.

All heating and ventilation equipment is grounded in accordance with the requirements of the EIC. The unit is mounted, tested, started in accordance with SP 73.13330.2016 Internal Sanitary Engineering Systems of Buildings.

The lamps are selected according to the environment characteristics and the room purpose. The lighting is controlled by switches installed near the entrance to the premises.

The following types of lighting are provided:

- working;

- outdoor;

- emergency.

Lamps with energy-saving lamps are used as light sources.

Protective earthing of electrical consumers is provided with a special additional wire (PE protective conductor).

The NS-АММА Pumping Station shall be loaded onto the vehicle by means of cranes of suitable lifting capacity, equipped with lifting means and pulling devices.

The NS-АММА Pumping Station may only be lifted by the elements provided for this purpose.

It is prohibited to lift the NS-АММА Pumping Station by other means.

The NS-АММА Pumping Station shall be secured to vehicles in accordance with the loading and securing specifications for each type of transport.

The dimensions of the NS-АММА Pumping Station comply with the requirements of the loading dimensions of the Technical Conditions for Loading and Securing Cargo of the Russian Ministry of Railway Communication.

AMMA guarantees that the NS-АММА Pumping Station complies with the technical documentation, provided the customer complies with the conditions of transport, storage, mounting and operation.

The warranty period is 12 (twelve) months from the date of mounting or 18 months from the date of delivery, whichever comes first.

The warranty periods for the components used in the НС-АММА Pumping Station are specified by the Manufacturer, who is responsible for their quality.

A warranty period may be agreed upon with the Customer.

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.