Станции насосные блочно-модульные НС-АММА

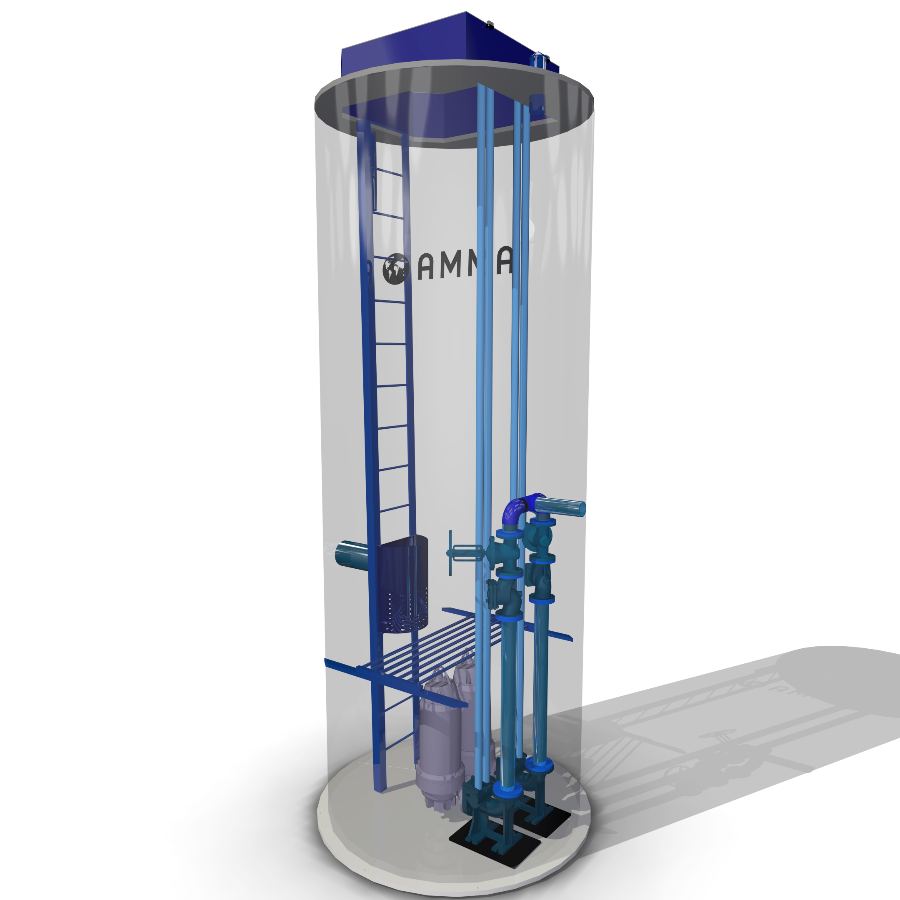

Канализационная насосная станция с укрытием КНС-АММА

DESCRIPTION

The KNS-АММА sewage stations are complete pumping stations. They are designed to collect and further pump drainage water, sewage waste and rainwater.

Pumped liquids:

- Drainage water;

- Rainwater (exposed water);

- Industrial and household wastewaters.

- KNS-АММА operates in the automated mode and allows to avoid the maintenance personnel constant supervision. The station is equipped with a control panel and Grundfos, Wilo or other pumps. When operating explosion-protected pumps, level sensors are connected to the control cabinet through an intrinsically safe barrier that would prevent sparking on the level sensor wire.

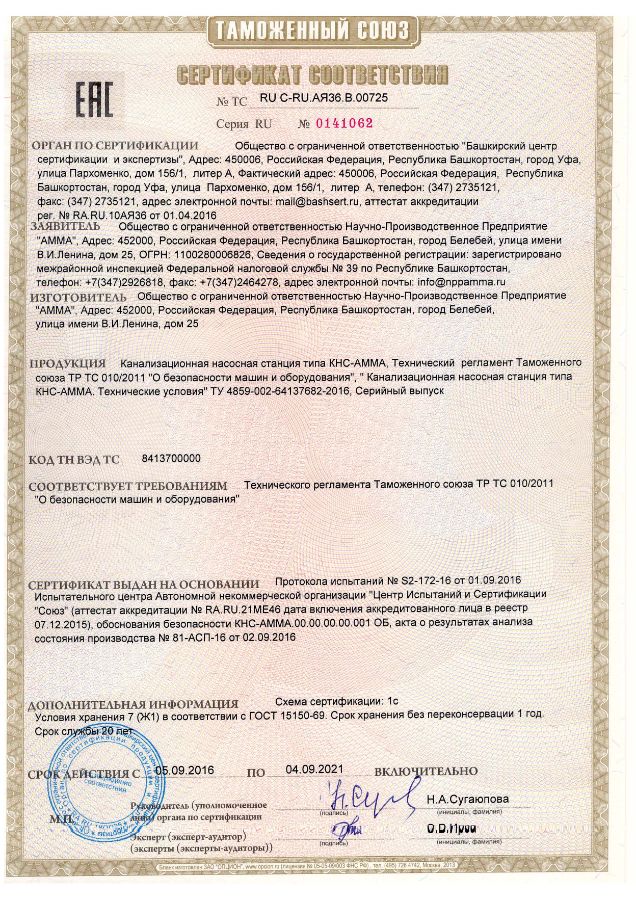

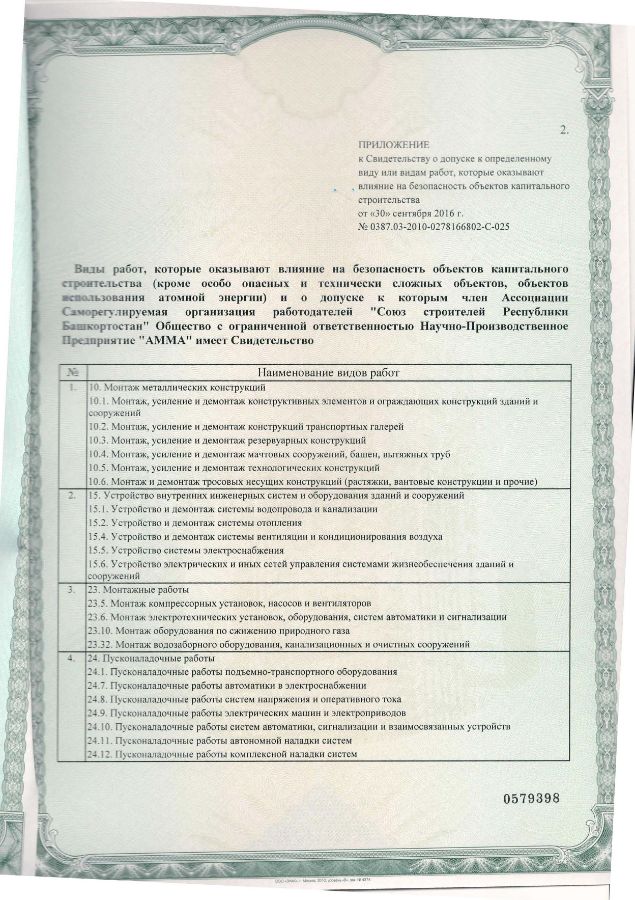

Our company manufactures sewage pumping stations. The quality of KNS-АММА is acknowledged with certificates of conformance.

KNS-АММА housing is made of polyethylene, fiberglass or metal. The sewage pumping station tank is made of the material resistant to concentrated acids, alkalis and solvents.

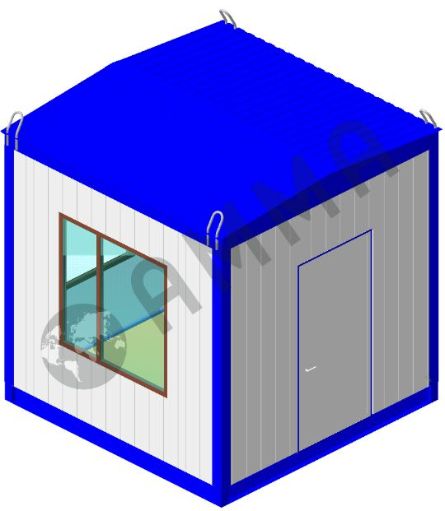

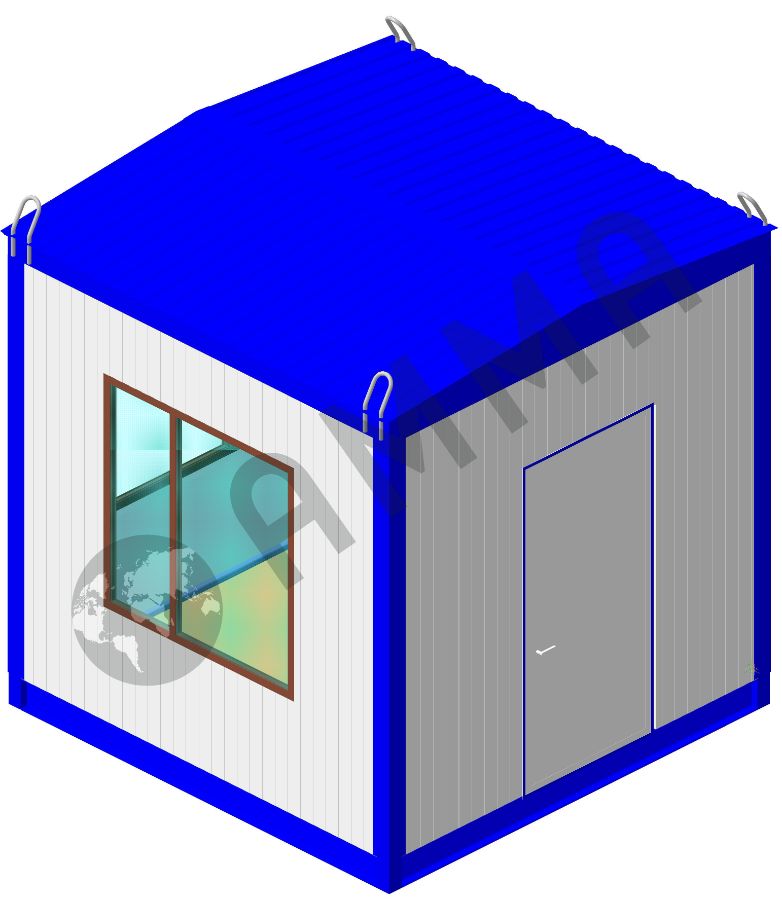

It is also possible to place a heat-insulated pavilion, a shelter for the pumping station.

The shelter has hoisting mechanisms, control hardware, a sanitary facility. The shelter is equipped with a ventilation system, heating and power. Before commissioning, the sewage pumping station undergo hydraulic tests to check if the KNS-АММА housing and piping are leak-proof.

In the modular container there is a control cabinet and a hoisting mechanism for lifting pumps.

SCOPE OF SUPPLY

The KNS-АММА scope of supply includes:

- Ready-to-operate modular container - 1 set;

- Control cabinet for the explosion-proof pumping station - 1 pc.;

- Explosion-proof power cabinet - 1 pc.;

- KNS-АММА complete housing - 1 pc.;

- Grundfos SE1.50.65.40.Ex.2.51D pumping unit - 2 pcs;

- Set of 4 explosion-proof floating switches;

- Set of as-built documentation;

- Spare parts kit;

- Bearing kits, Large SE1/SEV, Fr C — 1 kit;

- Kit, Shaft seal B/C22 — 1 kit;

- Oil - 3 l .

OPERATING PRINCIPLE

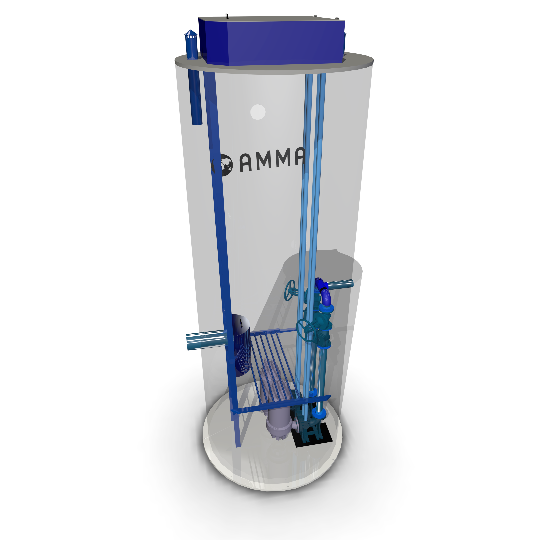

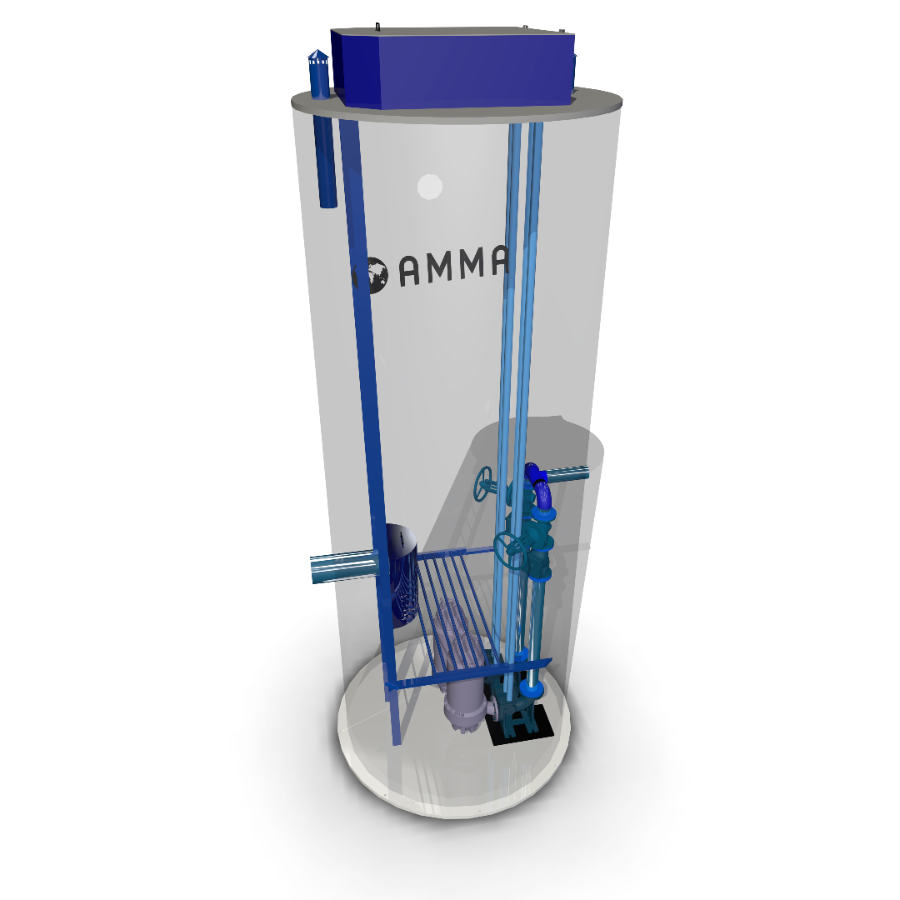

Feed pipelines bring waste water to the lower suction part of the station (suction tank), at the bottom of which there are pumping units.

The pumping units are installed on metal pedestals. The pedestals have a fastening unit with a tight gasket for feeding waste water under pressure to the pressure pipeline. There are guiding pipes for lifting and lowering pumping units, if needed during maintenance.

When turning on the working pump the waste water runs down the suction pipeline to the distribution chamber. In the chamber there are gate valves that allow to guide the waste water to the discharge pipelines. During KNS-АММА normal operation, al the gate valves in the pipelines are open.

The check valve installed in the pipeline of every pumping unit does not let the waste water get back into the pipeline of the backup pumping unit. All the gate valves are closed only when check valves are under repair or when failures in the system are being eliminated.

The trash collection basket is designed to collect large wastes that can enter the suction tank with waste water through the feeding pipeline and damage the submersible pumping units.

In the upper part of KNS there is a lid with a hatch. This allows access for the maintenance personnel to the inside of the KNS-АММА. If needed, it allows to take the pumping unit out down the guiding columns using a chain. It allows to take the trash basket out in order to empty it.

There is a ladder to descend down the KNS-АММА. In the top part there is a ventilation branch pipe for air exchange within the KNS-АММА.

In the side wall of the suction tank there are four universal floating sensors. Using the specified sensors the pumping units' operation is controlled automatically.

AUTOMATION SYSTEM

The level control is implemented with 4 Grundfos floating switches that timely start and stop the pumps and actuate the critical level emergency alarm. The sensors are connected to the LCD 108 control cabinet through LC-Ex 4 auxiliary cabinet (zener barrier).

The floating switch uses a micro switch protected with a smooth polypropylene membrane resistant to most aggressive fluids. In the main operation mode one pump is running. The pump starts when LSL1301 sensor gets under water.

Далее, если уровень воды продолжает повышаться, и срабатывает датчик LSH1301, то включается второй насос. При аварийном уровне воды срабатывает датчик LSHH1301. По мере снижения уровня воды насосы выключаются при срабатывании датчика LSLL1301.

Электрический пульт управления работой насосов расположен на поверхности в запирающемся щите на стойках или в помещении. При соответствии расхода поступающих сточных вод расчетным параметрам установленного оборудования, насосные агрегаты работают при нагрузках соответствующих требованиям завода изготовителя. При ручном или автоматическом (с помощью процессора) переключении насосов с «рабочего» на «резервный» происходит равномерный износ, снижается вероятность отказов оборудования, отпадает необходимость в дорогостоящих ремонтах, что снижает затраты на эксплуатацию оборудования.

AMMA guarantees that the KNS-АММА sewage pumping station with a shelter complies with the technical documentation, provided the customer maintains the conditions of transport, storage, mounting and operation.

The warranty period is 12 (twelve) months from the date of mounting or 18 months from the date of delivery, whichever comes first. The services life of KNS-АММА with a shelter is 8 years.

The warranty periods of the components used in the KNS-АММА with a shelter are established by the manufacturers of these products, who are responsible for their quality.

A warranty period may be agreed upon with the Customer.

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.