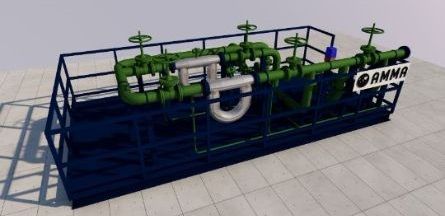

ББТ-АММА PROCESS MODULAR CONTAINERS

Water metering unit

INTENDED USE AND DESCRIPTION

The unit meters the flow rate and controls the parameters, transmits the data to the data processing system.

The amount and diameter of metering pipelines is defined depending on the maximum flow rate and the type of applied flow transducers.

The flows between metering lines can be controlled both manually and automated.

The water metering unit is produced and delivered to the Customer in the ultimate ready-to-use condition. It is mounted onto a specially prepared grillage standing on piles or onto a reinforced concrete foundation.

The production follows a customized project with regards to all the requirements of the Customer.

Water metering units can be released for frigid climate areas.

The units allow transportation by road, rail or air.

ADVANTAGES

Advantages of the unit:

- easy to use;

- climatic version is F;

- use of only modern, environmentally friendly materials;

- superior workmanship of the released products;

- guaranties of the excellent work;

- short installation;

- easy to transport;

- ready-to-operate condition means the item can be put into operation straightaway;

- low cost.

SCOPE OF SUPPLY

The NPP AMMA, LLC scope of delivery includes:

- ready-to-operate reservoirs;

- external supports and consumables for mounting;

- set of spare parts and materials for the warranty period;

- technical documentation (data sheet, operation manual).

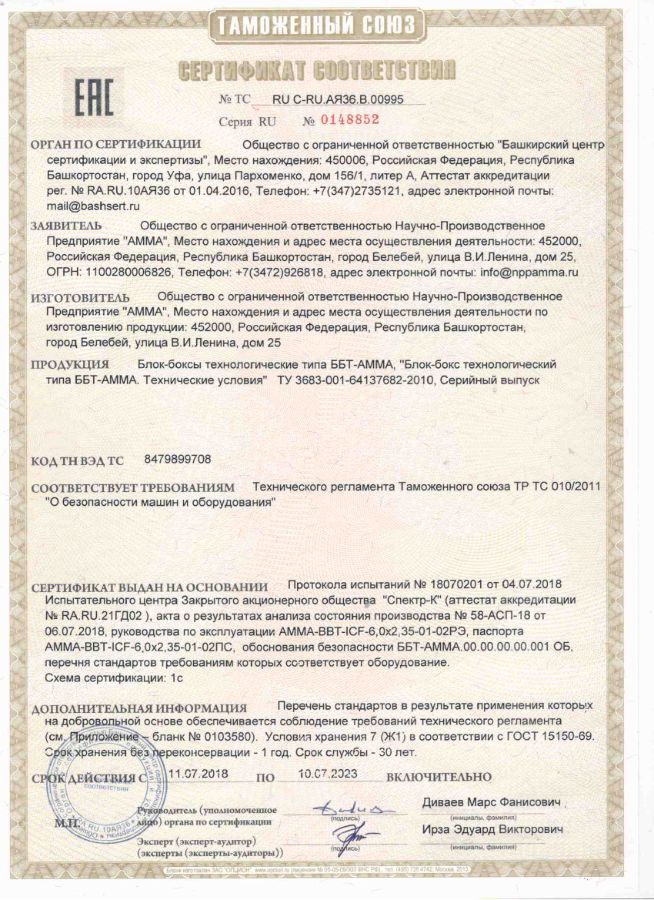

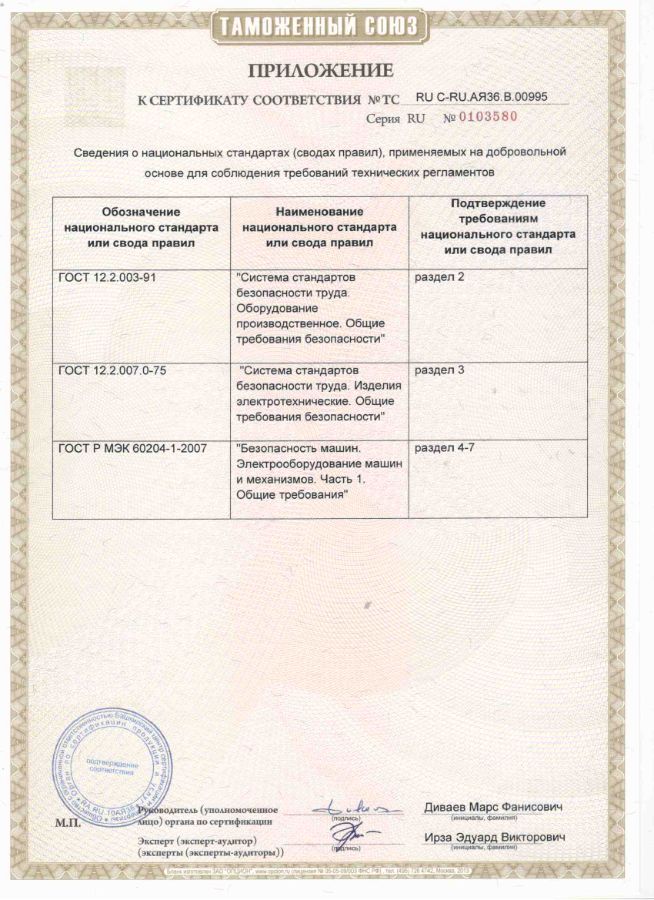

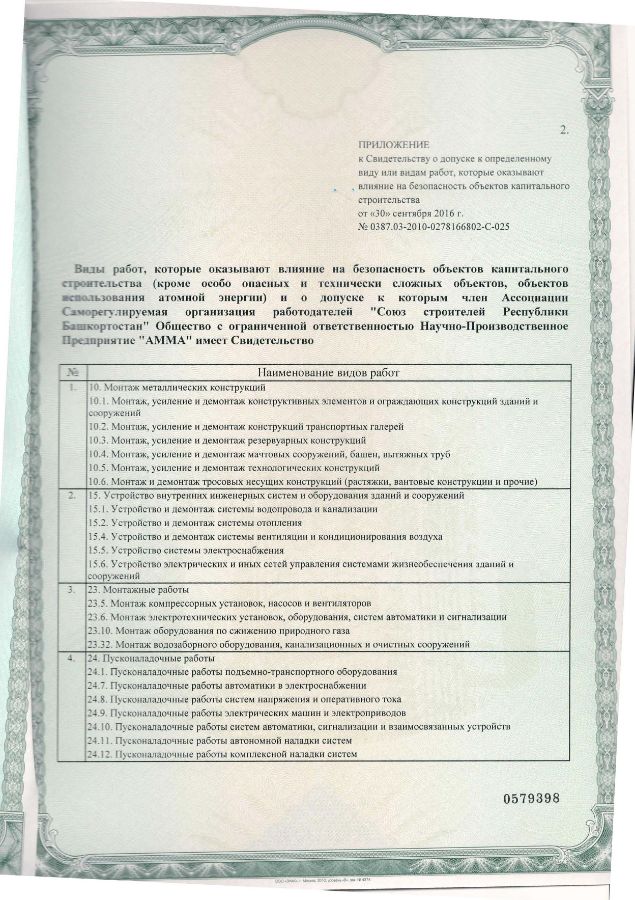

QUALITY

Metal structures are manufactured in accordance with the requirements of GOST 23118-2012 Steel Construction Structures and SP 53-101-98 Fabrication and Quality Control of Steel Construction Structures. The load-bearing structures and piping are exposed to a corrosion protection treatment.

Process pipelines are mounted in accordance with GOST 32569-2013 Industrial steel pipelines. Requirements for design and operation in explosive and chemically dangerous industries, approved by order of the Federal Agency for Technical Regulation and Metrology dated 08.04.2014. N331-cт, SNiP 3.05.05-84 Process equipment and pipelines.

The water metering unit's automation includes:

- Collecting and transmitting signals from the mass flowmeters to the automation cabinet.

- the data of the current water metering unit flow rate is transmitted through a pulse-frequency signal (24V DC);

The electricity supply is of III category of reliability. The voltage is 380/220V.

The consumers are supplied with power through a ЩР explosion-proof distribution cabinet located on the right from the unit entrance.

The power distribution network is made with a copper wire armoured cable with PVC membrane. The cables run through metal structures in the water metering unit.

The electrical wiring is selected in accordance with GOST R 50571.5.52-2011 Electrical Wiring and the EIC, Edition 7, Section 7, Chapter 7.1.

The pipelines and flow meters are heated with a self-regulating cable controlled with the temperature on the thermostat.

For electrical safety purposes bare conducting parts have neutral grounding with special conductors connected with a separate clamp to the PE conductors, main and auxiliary equipotential bonding systems.

Protective earthing of electrical consumers is provided with a special additional wire (PE protective conductor).

The NPP АММА water metering unit shall be loaded onto the vehicle by means of cranes of suitable lifting capacity, equipped with lifting and pulling devices.

The NPP АММА water metering unit is allowed to be lifted only using the elements designed for lifting.

Otherwise lifting of the NPP АММА water metering unit is prohibited.

The NPP АММА water metering unit should be secured in the vehicle in accordance with the technical specifications for handling and securing cargoes for a particular type of transport. The overall dimensions of the NPP АММА water metering unit comply with the requirements of the handling dimensions from the Technical Specifications for Handling and Securing Cargoes of the Ministry of Transport and Communication of Russia.

AMMA guarantees that the NPP АММА water metering unit complies with the technical documentation, provided the customer maintains the conditions of transport, storage, mounting and operation.

The warranty period is 12 (twelve) months from the date of mounting or 18 months from the date of delivery, whichever comes first.

The warranty periods for the components used in the NPP АММА water metering unit arespecified by the manufacturer, who is responsible for their quality.

A warranty period may be agreed upon with the Customer.

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.