БЛОКИ ТЕХНОЛОГИЧЕСКИЕ БТТ

Suction Wells

INTENDED USE AND DESCRIPTION

The suction (discharge) well is designed to suck crude oil, petroleum and other oil products from tanker trucks and discharge them into vessels (tanks).

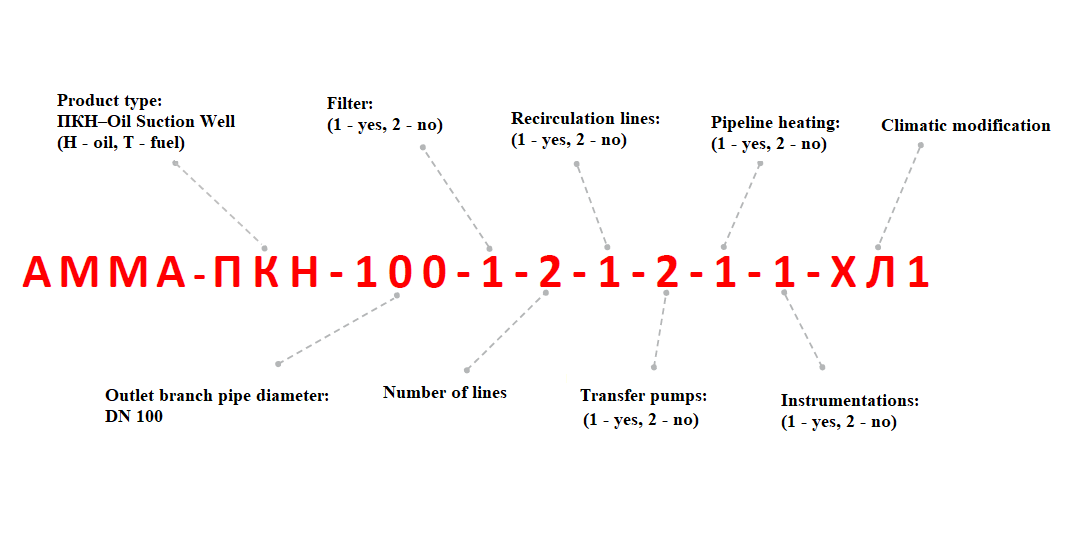

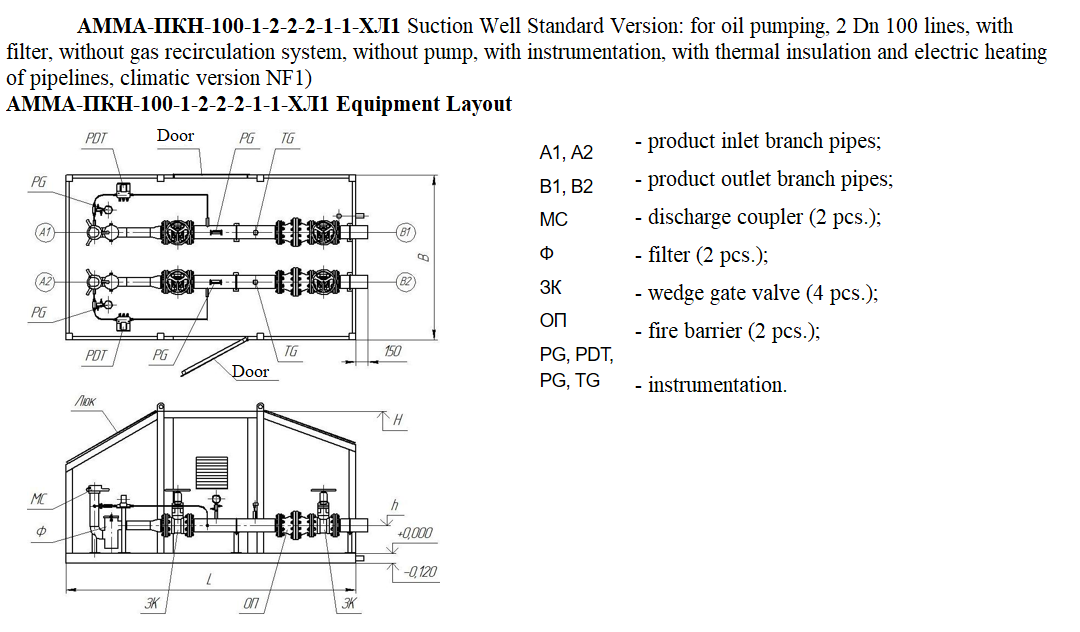

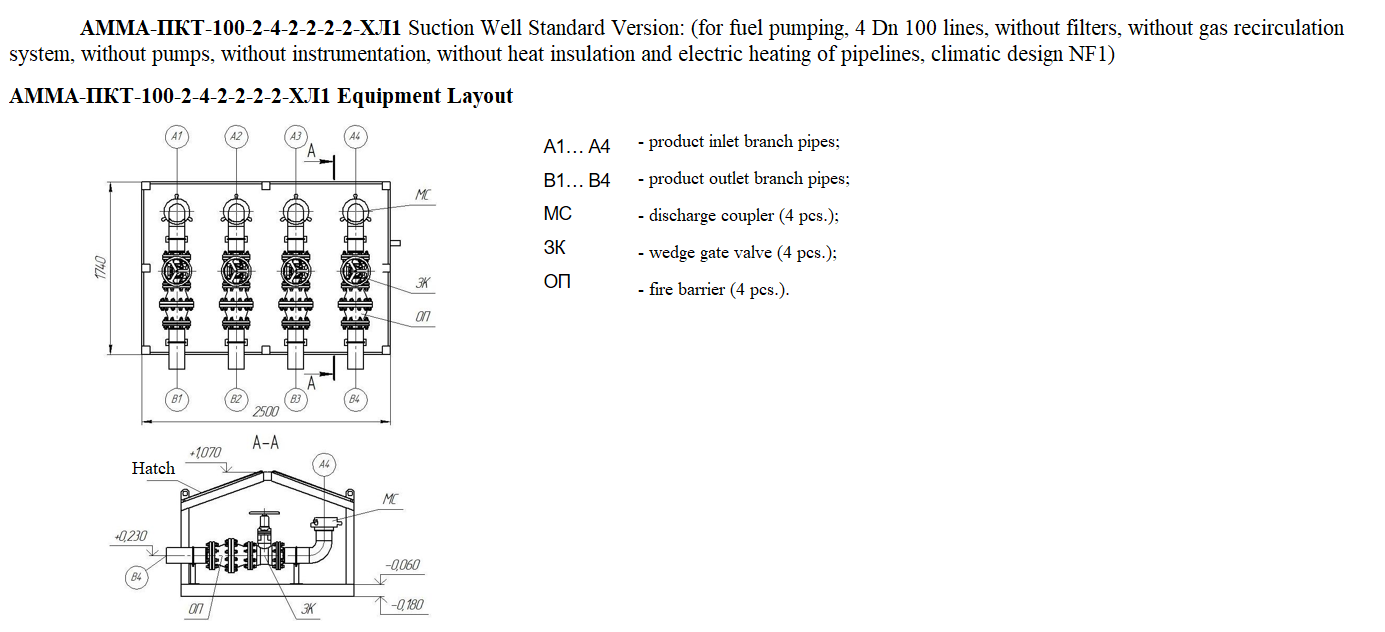

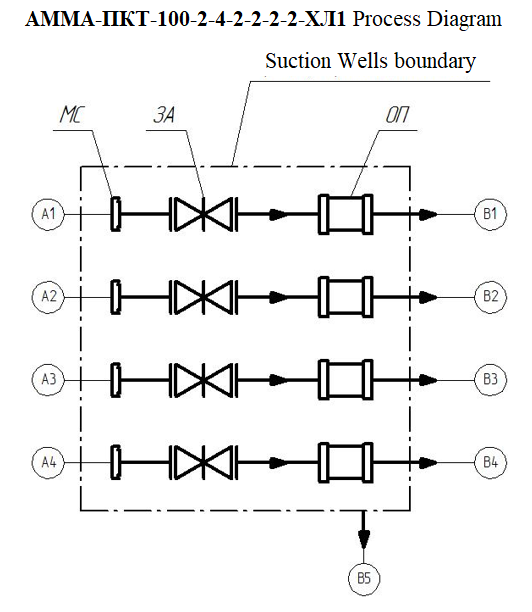

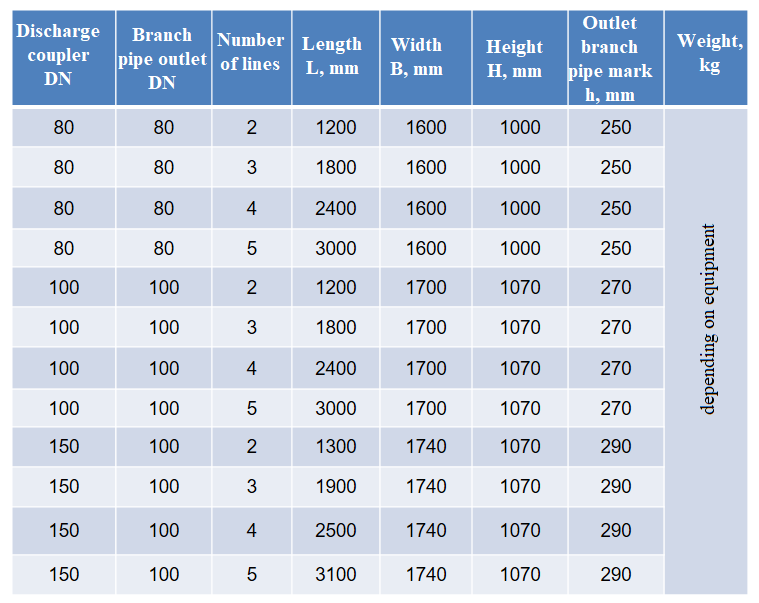

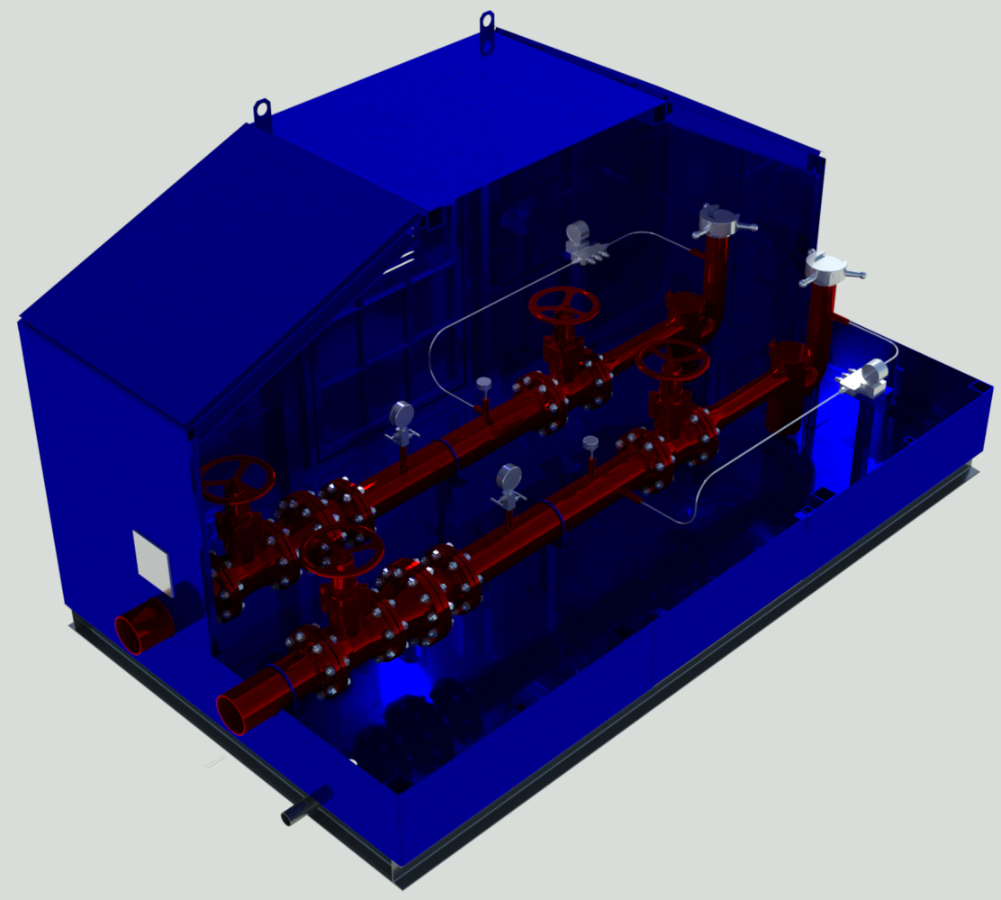

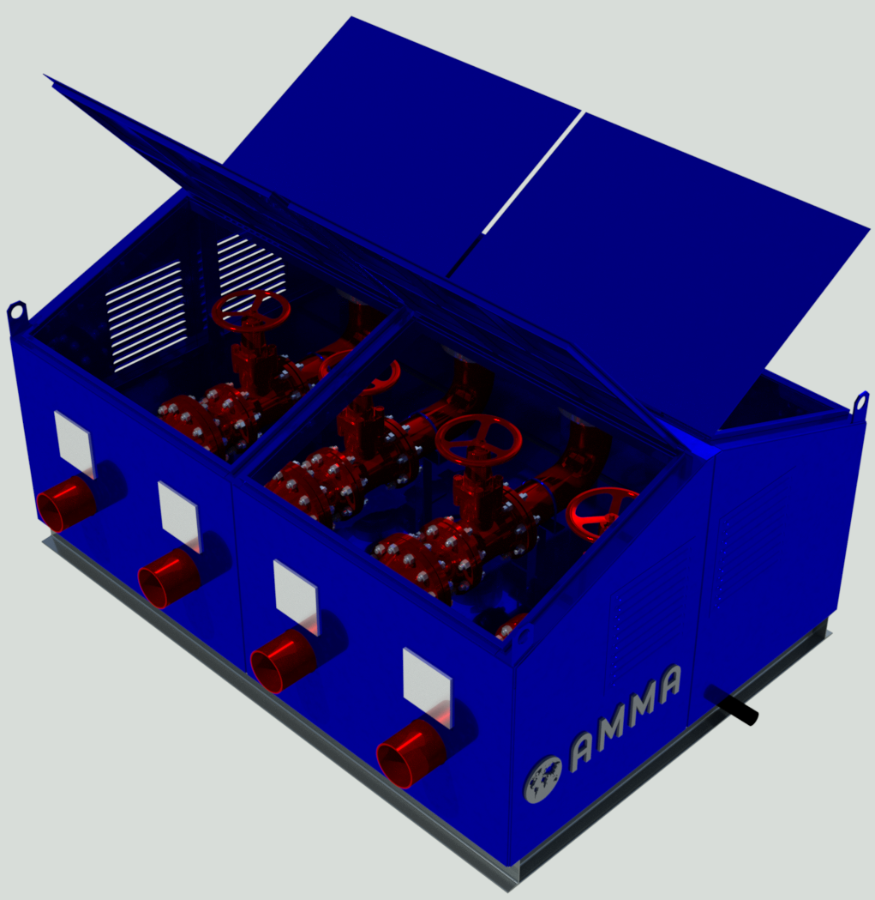

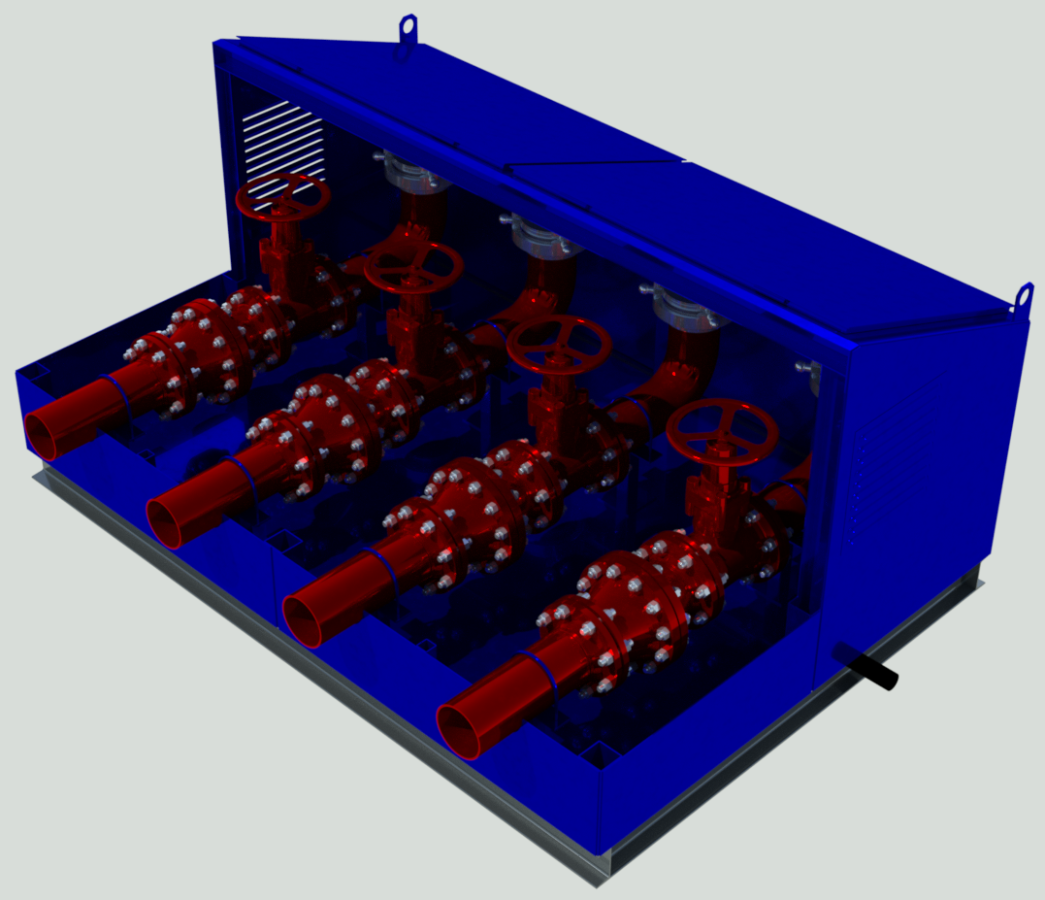

Upon the customer's request the well can include from 2 to 5 product discharge lines with different nominal diameters, complete sets and instrumentations.

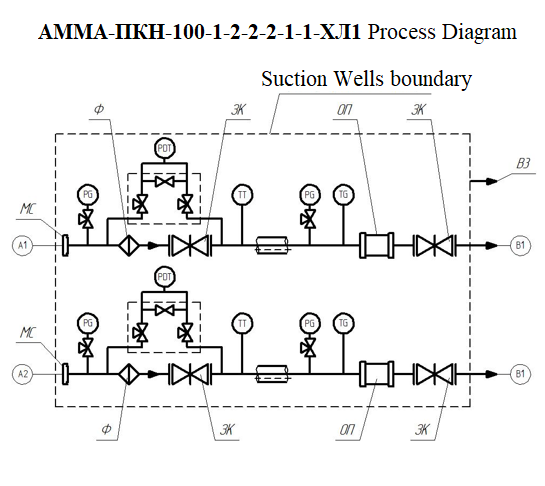

The tanker truck discharge hose is connected with a QCDC discharge coupler.

The product flows under gravity, is pumped with the tanker truck pump or pumped with the well pump..

The filter used in the pipeline allows maintaining the filtering element without dismantling the entire filter.

The discharge lines can be completed with a fuel vapor recirculation system. The ensures safe and environmentally friendly operation.

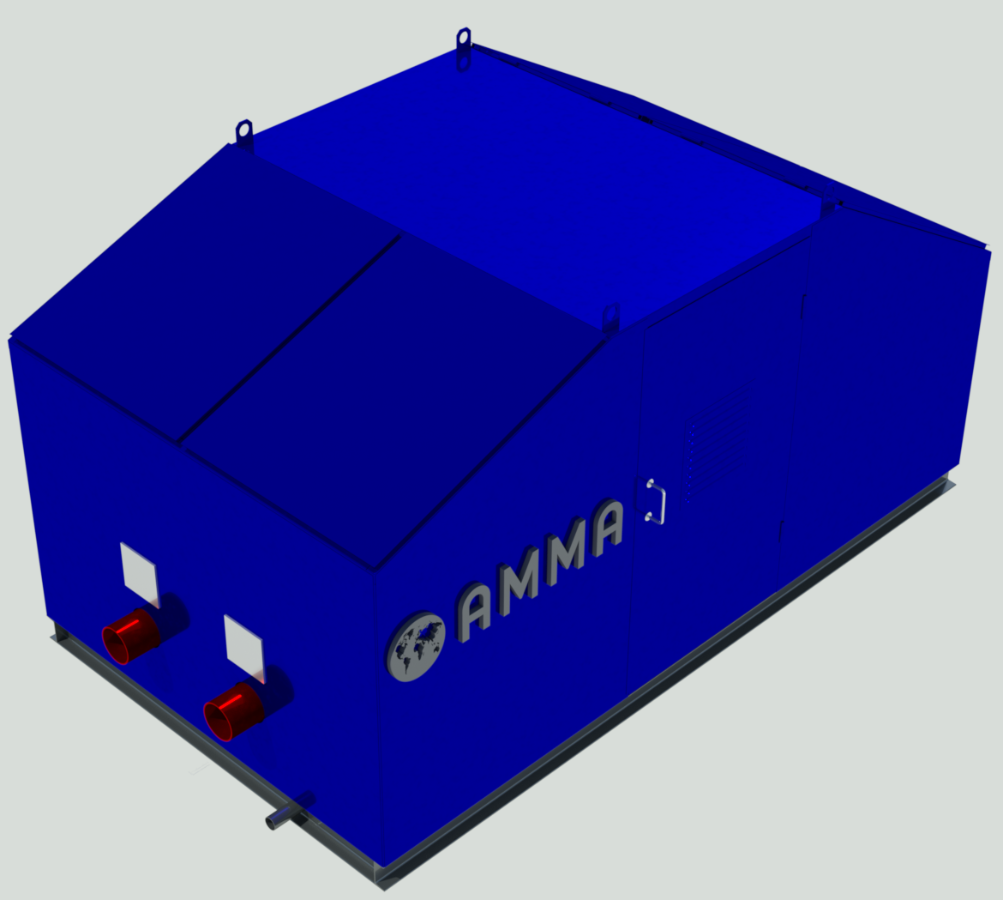

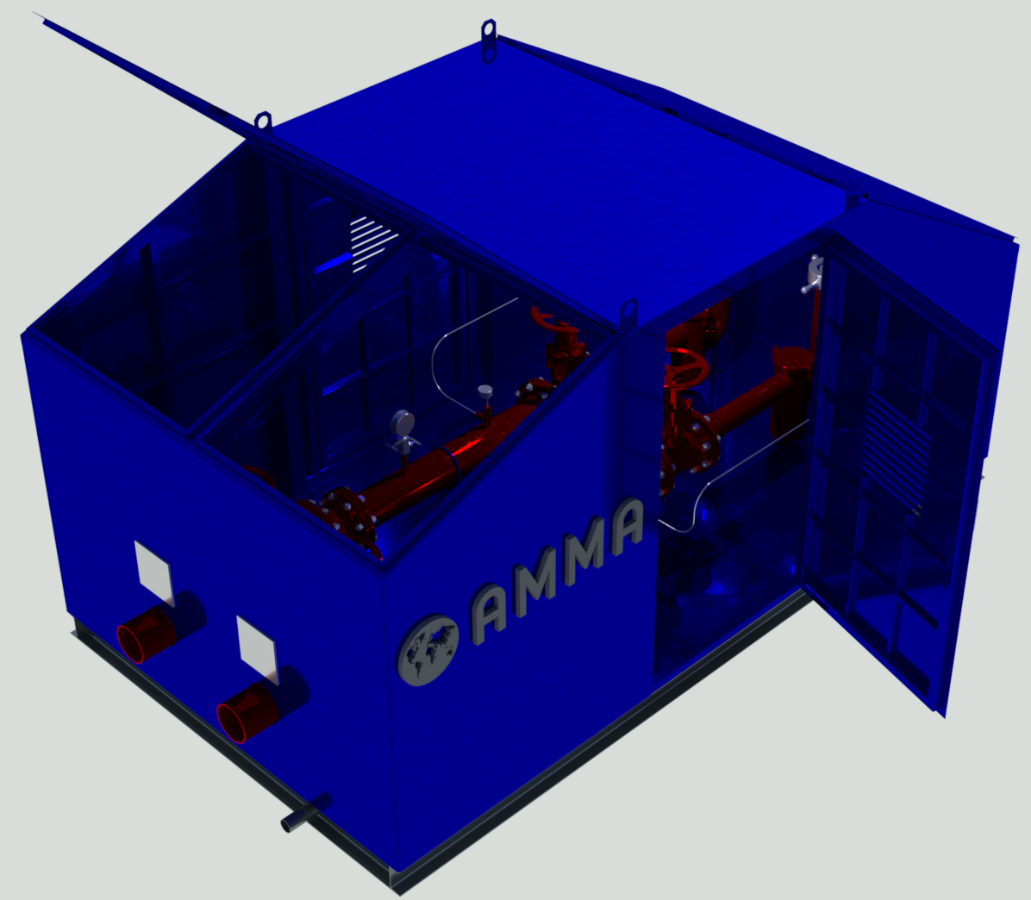

The wells are delivered to the facility/site as a ready skid or container in the ready-to-operate condition. To put the well into operation it is enough to install it on a platform or a foundation and connect it to the site's pipelines.

The standard complete set is a special skid or container with doors and lids with pipelines and a suction branch pipe (discharge coupler), shutoff valves, control instruments inside. Branch pipes for connecting to pipelines for discharging oil product into the vessels outside the well. The modular container is equipped with branch pipe for discharging the fluid from the bottom into the drainage system.

The extended complete set can also include:

- A filter with a quick access to the filtering element fro maintenance and to the filtering element control system.

- A drainage pipeline.

- A fuel vapor recirculation system.

- A transfer pump.Instruments: a thermometer, a pressure gauge, temperature and pressure sensors.

- Heat insulation for the pipeline with a pipeline electrical heating system.

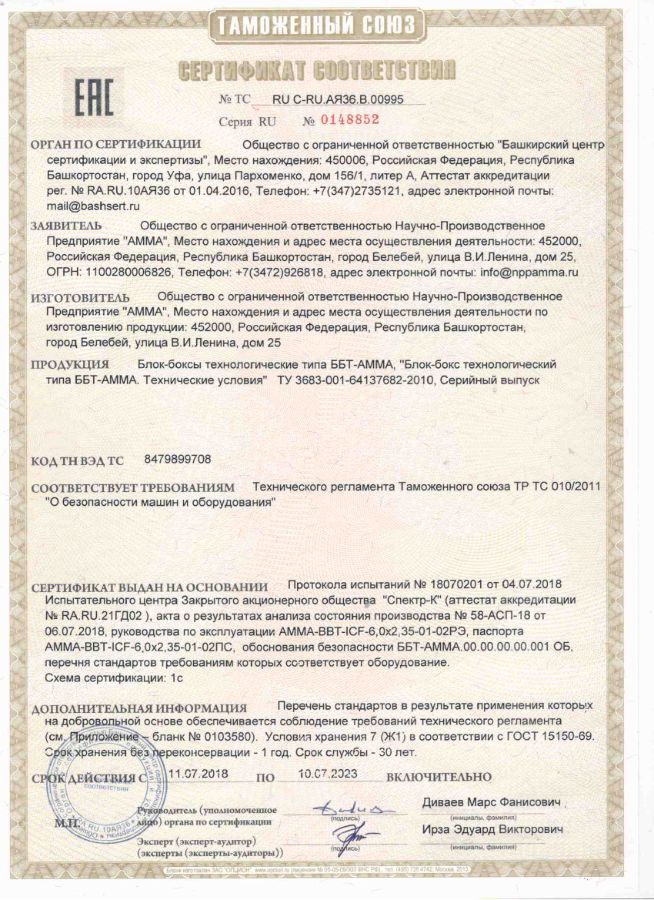

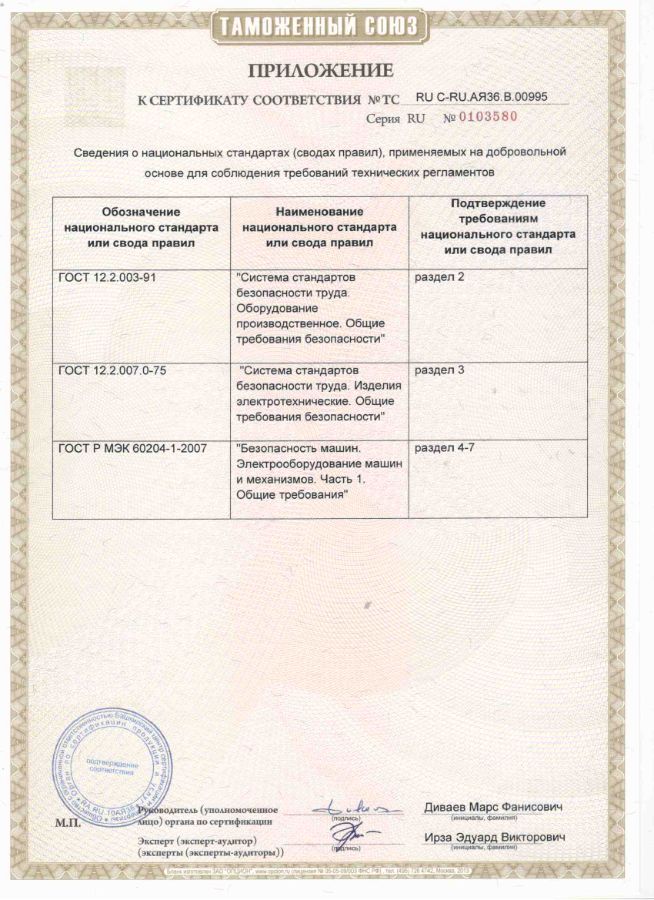

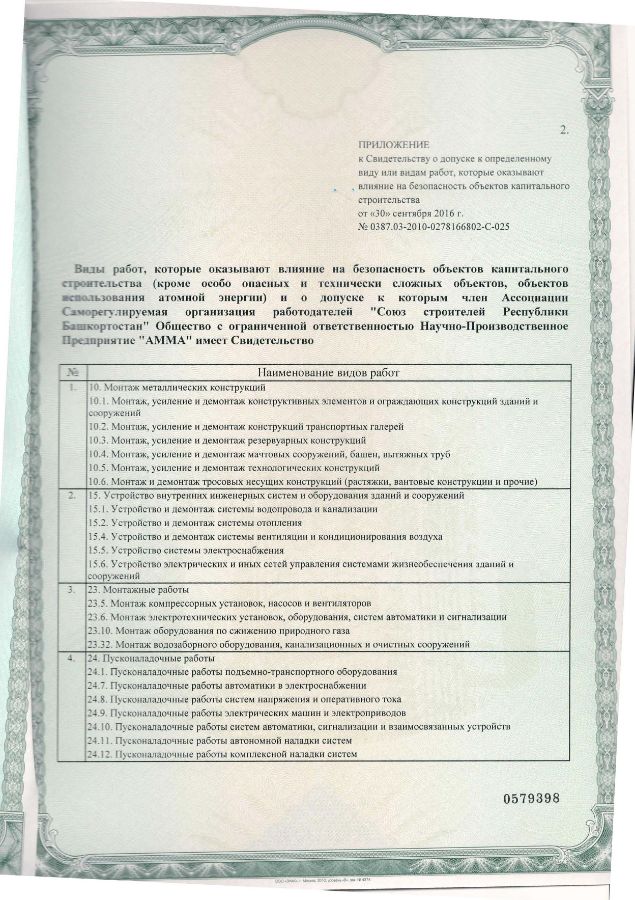

The metal structures and pipelines are designed and manufactured in compliance with the main regulatory requirements:

- GOST 32569-2013 Process steel pipelines. Requirements to design and operation in explosive and chemically dangerous production facilties.

- GOST 23118-2012 Construction steel structures.

- SP 53-101-98 Production and quality control of steel construction structures.

- Industrial safety federal codes and regulations Safety Regulations for Oil and Gas Industry.

- Rules of technical operation and safety of electrical installations at industrial facilities.

The doors and lids have an intrinsically safe structures, they protect the well cavity from precipitations. They allow a free access to the filter, valves and instrumentation for their maintenance.

The safe operation is ensured with a reliable insulation of electrical elements, instrumentation grounding of the devices, pipelines, valves, well housing.

The bearing structures and pipelines are exposed to the anticorrosion treatment, they can be painted in the customer's brand colours. The pipelines are hydraulically tested for strength and leakage during the manufacturing process.

Для предотвращения возможного скопления вредных и взрывоопасных паров топлива внутри колодца предусмотрена естественная вентиляция постоянного действия через вентиляционные решетки и жалюзи.

В колодцах, предназначенных для слива вязких при низких температурах жидкостей предусматривается электрообогрев и теплоизоляция трубопроводов.

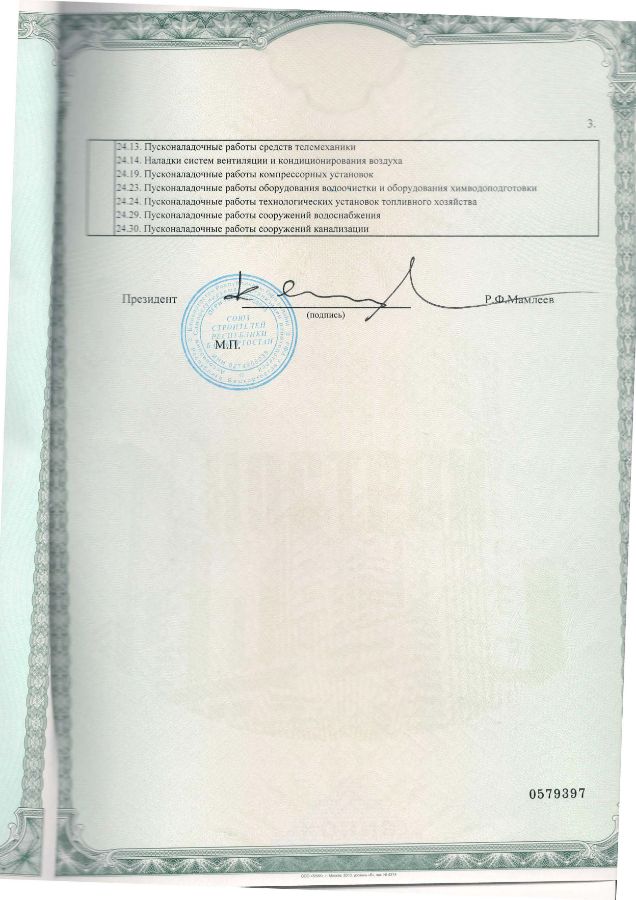

Питание электроэнергией осуществляется от внешней питающей сети. Электроснабжение выполняется по I категории надежности.

Электрообогрев трубопроводов ПК выполняется греющей лентой с управлением от термостатов по температуре внутри блока.

Электропроводка сети выполнена по системе TN-S.

Предусмотрено заземление трубопроводов, металлоконструкций и электроаппаратуры с выводами для подключения к внешнему контуру заземления.

В приемном колодце прокладывается внутренний контур заземления из стальной полосы 4х25 мм.

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.